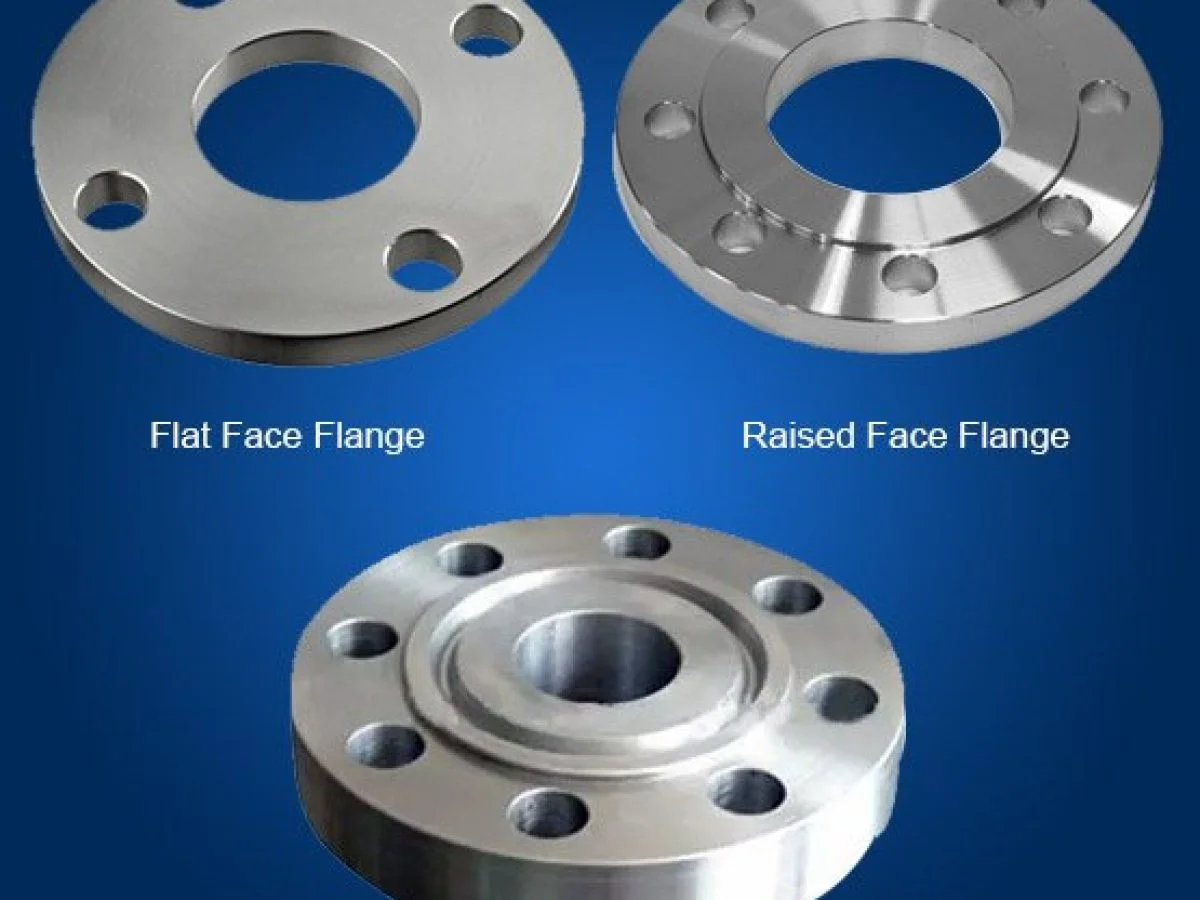

Flat face flanges are typically used in low-pressure or equipment-sensitive applications, while raised face flanges are preferred for higher pressure and temperature services where stronger gasket sealing is required. The difference lies in flange face geometry, gasket compression behavior, and system compatibility, not just appearance. Choosing the wrong type can lead to leakage, flange damage, or long-term maintenance issues.

Understanding these differences is essential when sourcing flanges from a flat face flange factory or specifying components for industrial piping systems.

A flat face flange has a fully flat sealing surface that extends across the entire flange face, matching the surface of the mating flange.

Flat face flanges are commonly used when:

Connecting to cast iron or ductile iron equipment

Equipment flanges cannot tolerate bending stress

Full-face gaskets are required to distribute load evenly

Because the contact surface is uniform, bolt loads are spread over a larger area, reducing localized stress on the flange and connected equipment.

A raised face flange features a small raised sealing surface around the bore, designed to concentrate gasket compression in a narrower area.

Raised face flanges are widely used in:

ASME B16.5 piping systems

Medium- and high-pressure applications

Steel-to-steel flange connections

The raised portion allows for higher gasket stress, improving sealing performance under pressure and temperature fluctuations.

They can be connected, but modification is usually required.

When a flat face flange is mated with a raised face flange:

The raised face must typically be machined flat

A full-face gasket should be used

Uneven stress must be avoided to protect cast or brittle equipment

From a manufacturing perspective, a reliable flat face flange factory will often supply flat face flanges specifically designed to match equipment interfaces, reducing the need for on-site modification.

Gasket selection is one of the most critical differences.

Flat face flange

Uses full-face gaskets

Gasket covers the entire flange face

Bolt holes are included in the gasket design

Raised face flange

Uses ring gaskets or spiral wound gaskets

Gasket contacts only the raised sealing area

Higher sealing stress is achieved with lower bolt load

Using the wrong gasket type can compromise sealing performance regardless of flange quality.

Raised face flanges are generally better suited for higher pressure and temperature service.

The raised sealing surface:

Increases gasket compression

Improves sealing efficiency

Performs better under thermal cycling

Flat face flanges are typically limited to lower pressure ratings, often up to 300#, depending on material and standard. This is why flat face flanges are commonly found in water systems, utilities, and equipment connections rather than high-pressure pipelines.

Cast iron and similar materials are more brittle and sensitive to bending stress.

A flat face flange:

Eliminates bending moments caused by raised sealing surfaces

Reduces the risk of cracking equipment flanges

Provides uniform gasket compression

For this reason, many equipment manufacturers explicitly require flat face flanges, and sourcing them from an experienced flat face flange factory ensures dimensional accuracy and surface flatness.

Standards play a significant role in flange selection.

ASME B16.5 defaults to raised face flanges for most pressure classes

Flat face flanges are specified for special cases, especially when connecting to equipment

DIN standards more commonly include flat face configurations in certain pressure ranges

Understanding the applicable standard helps ensure compatibility with mating components and inspection requirements.

Yes, significantly.

Flat face flanges:

Require careful gasket alignment

Often use larger gaskets

Are more forgiving to equipment flanges

Raised face flanges:

Require precise bolt torque control

Are more sensitive to surface finish

Offer better long-term sealing in demanding service

From a lifecycle perspective, the correct flange face selection reduces maintenance frequency and unplanned downtime.

Selection should be based on:

Pressure and temperature conditions

Type of connected equipment

Applicable standards

Gasket design

Long-term maintenance strategy

Working with a qualified flat face flange factory or flange manufacturer ensures the product is matched to real operating conditions rather than generic assumptions.

| Aspect | Flat Face (FF) | Raised Face (RF) |

Sealing Surface | Fully flat | Raised sealing area around bore |

Gasket Type | Full-face gasket | Spiral wound or ring gasket |

Pressure Capability | Low to moderate | Moderate to high |

Load Distribution | Uniform across flange face | Concentrated on raised area |

Equipment Protection | Excellent for brittle equipment | Not recommended for cast iron |

Typical Standards | DIN / EN, special ASME cases | ASME B16.5 default |

Common Applications | Pumps, valves, cast iron equipment | Steel piping systems |

Installation Sensitivity | More forgiving | Requires precise torque control |

Manufacturing Focus | Flatness accuracy | Surface finish & raised height |

Typical Supplier | Flat face flange factory | General flange manufacturer |

Flat face flanges and raised face flanges are designed for different mechanical and sealing requirements.

Flat face flanges protect sensitive equipment and provide uniform load distribution

Raised face flanges deliver stronger sealing performance for higher pressure systems

For industrial piping systems, correct selection—supported by proper manufacturing and standards compliance—ensures safe operation, reduced leakage risk, and long service life.

Hot Extrusion vs Piercing in Nickel Alloy Seamless Pipe ProductionJanuary 19, 2026Hot extrusion is generally preferred for high-alloy, difficult-to-deform nickel alloys, while piercing (Mannesmann process) is widely used for carbon steel and lower-alloy seamless pipes. In nickel al...view

Hot Extrusion vs Piercing in Nickel Alloy Seamless Pipe ProductionJanuary 19, 2026Hot extrusion is generally preferred for high-alloy, difficult-to-deform nickel alloys, while piercing (Mannesmann process) is widely used for carbon steel and lower-alloy seamless pipes. In nickel al...view The Complete Guide to Premium Stainless Steel Butt-Welded Fittings from Fujian Guangxin PipeTechJuly 1, 2025Leaking flanges causing downtime? Our precision stainless steel butt-welded fittings form permanent, leak-proof connections built for high-pressure, corrosive, and extreme-temperature applications. Fu...view

The Complete Guide to Premium Stainless Steel Butt-Welded Fittings from Fujian Guangxin PipeTechJuly 1, 2025Leaking flanges causing downtime? Our precision stainless steel butt-welded fittings form permanent, leak-proof connections built for high-pressure, corrosive, and extreme-temperature applications. Fu...view Common Standards for Duplex Stainless Steel Pipes (ASTM, ASME, EN)January 19, 2026Duplex stainless steel pipes are commonly specified under ASTM material standards, ASME pressure piping codes, and EN European norms, depending on project location, service conditions, and regulatory ...view

Common Standards for Duplex Stainless Steel Pipes (ASTM, ASME, EN)January 19, 2026Duplex stainless steel pipes are commonly specified under ASTM material standards, ASME pressure piping codes, and EN European norms, depending on project location, service conditions, and regulatory ...view Material Selection for Integral Flanges: A105 vs Alloy SteelJanuary 19, 2026Carbon steel A105 is typically selected for integral flanges in moderate pressure and temperature services, while alloy steel is chosen when higher temperature strength, creep resistance, or enhanced ...view

Material Selection for Integral Flanges: A105 vs Alloy SteelJanuary 19, 2026Carbon steel A105 is typically selected for integral flanges in moderate pressure and temperature services, while alloy steel is chosen when higher temperature strength, creep resistance, or enhanced ...view Common Standards Used for Integral Flanges (ASME, API, EN)January 19, 2026Integral flanges are typically specified under ASME, API, or EN standards, depending on the pressure class, application environment, and regional compliance requirements. In practice, ASME standards d...view

Common Standards Used for Integral Flanges (ASME, API, EN)January 19, 2026Integral flanges are typically specified under ASME, API, or EN standards, depending on the pressure class, application environment, and regional compliance requirements. In practice, ASME standards d...view Application Fields of Stainless Steel Seamless PipesSeptember 15, 2025Why Stainless Steel Seamless Pipes Are Essential in Modern IndustriesStainless steel seamless pipes are widely recognized for their durability, corrosion resistance, and ability to perform under high-...view

Application Fields of Stainless Steel Seamless PipesSeptember 15, 2025Why Stainless Steel Seamless Pipes Are Essential in Modern IndustriesStainless steel seamless pipes are widely recognized for their durability, corrosion resistance, and ability to perform under high-...view