When it comes to choosing the right piping solution for industrial applications, one of the most common questions buyers face is: "Should I choose seamless pipes or welded pipes?"

The answer depends on your project's pressure requirements, budget, and application environment — but let's break it down from an industry expert's perspective.

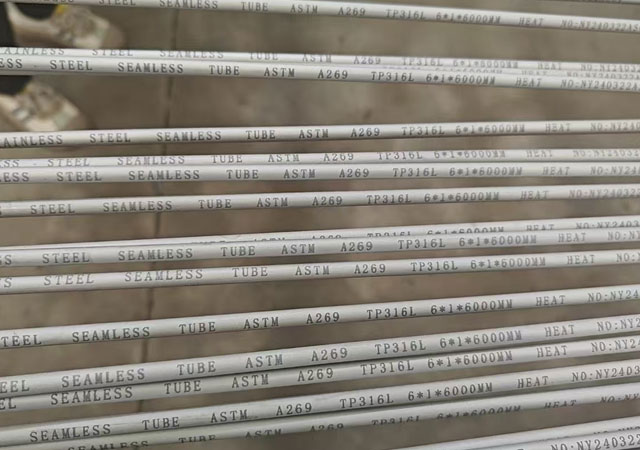

Seamless pipes are manufactured without a welded seam. They are produced through a solid round steel billet that is heated and pierced to form a hollow tube, then elongated to the desired length and thickness.

Because seamless pipes have no welded joint, they offer:

Higher strength and uniform structure

Excellent pressure resistance

Better performance under extreme temperatures and corrosive environments

These properties make seamless pipes the preferred choice for critical industries such as:

Oil and gas transmission

High-pressure boilers

Petrochemical processing

Offshore applications

Welded pipes, on the other hand, are made by rolling a steel plate or strip into a cylindrical shape and welding the seam — either longitudinally or spirally. After welding, the pipe undergoes processes like heat treatment and inspection to ensure structural integrity.

Welded pipes are ideal for low to medium pressure applications, offering:

Cost efficiency

Uniform wall thickness

Availability in larger diameters and lengths

They are widely used in:

Water transportation systems

Structural applications

General engineering purposes

| Feature | Seamless Pipes | Welded Pipes |

Manufacturing Process | Extruded from a solid billet | Formed and welded from steel plate or coil |

Seam | No seam – fully homogeneous | Has a longitudinal or spiral seam |

Strength | Higher mechanical strength | Slightly lower strength due to weld area |

Pressure Handling | Suitable for high-pressure and high-temperature service | Best for low to medium pressure systems |

Cost | More expensive due to complex manufacturing | More economical and easier to produce |

Size Range | Limited to smaller diameters (typically ≤ 24") | Available in larger diameters (up to 120") |

Inspection | Requires ultrasonic or eddy current testing | Requires weld integrity testing (X-ray, hydrostatic, etc.) |

When safety and performance are non-negotiable — for example, in oil exploration, chemical plants, or power generation systems — seamless pipes are the industry standard.

Because they lack a welded seam, they eliminate the weak point typically associated with welded pipes. This makes them particularly suitable for:

High-pressure fluid transportation

Thermal power systems

Refineries and offshore platforms

Moreover, seamless pipes have a more consistent roundness and thickness, resulting in better flow efficiency and reduced pressure drop over long distances.

From a commercial standpoint, cost-effectiveness plays a major role in material selection.

Seamless pipes involve higher production costs due to precision manufacturing and quality testing.

Welded pipes are more affordable and suitable for non-critical applications, such as structural support or low-pressure lines.

However, in long-term operations, the durability and reduced maintenance of seamless pipes often translate into lower lifecycle costs, especially in high-risk industries.

Both seamless and welded pipes follow international standards like:

ASTM A312 – Austenitic stainless steel seamless and welded pipes

ASTM A106 / A53 – Carbon steel pipes

API 5L – Line pipes for oil and gas

Common stainless steel grades include 304, 304L, 316, 316L, and 321, each selected based on corrosion resistance, strength, and service conditions.

The choice between seamless and welded pipes depends on:

Operating pressure and temperature

Corrosive or non-corrosive environment

Budget constraints

Pipe diameter and thickness requirements

In high-pressure or high-temperature environments, seamless pipes are typically the preferred choice.

For structural or low-pressure systems, welded pipes offer a more economical alternative without sacrificing functionality.

At GxpipeTech, we specialize in manufacturing and supplying high-quality stainless steel seamless pipes and fittings for industrial use.

With years of experience serving global distributors and EPC contractors, we understand the precise technical standards and project demands of the energy, petrochemical, and construction sectors.

Our seamless pipes are:

Manufactured under strict quality control

Certified to international standards (ASTM, ASME, EN, ISO)

Available in custom dimensions and finishes

Whether you need pipes for high-pressure steam lines, offshore platforms, or refinery applications, our technical team ensures that every product delivers maximum reliability and performance.

In summary, the main difference between seamless and welded pipes lies in their manufacturing process and performance capabilities.

Seamless pipes offer superior strength and reliability for demanding environments, while welded pipes provide an economical solution for general applications.

When performance, safety, and long-term durability matter, seamless pipes remain the professional' choice — and GxpipeTech is here to deliver them with precision and quality you can trust.

Industrial Pipe Flanges: Types and ApplicationsJuly 1, 2025Leaking pipe connections costing you time and money? The right flange can make all the difference. Flanges provide secure, leak-proof joints in pipelines, valves, and equipment—but choosing the wrong...view

Industrial Pipe Flanges: Types and ApplicationsJuly 1, 2025Leaking pipe connections costing you time and money? The right flange can make all the difference. Flanges provide secure, leak-proof joints in pipelines, valves, and equipment—but choosing the wrong...view Flat Face Flange vs Raised Face vs RTJ: Which One to Choose?January 19, 2026Flat face flanges are selected for equipment-sensitive and low-pressure systems, raised face flanges suit most standard industrial piping, and RTJ flanges are used in high-pressure, high-temperature, ...view

Flat Face Flange vs Raised Face vs RTJ: Which One to Choose?January 19, 2026Flat face flanges are selected for equipment-sensitive and low-pressure systems, raised face flanges suit most standard industrial piping, and RTJ flanges are used in high-pressure, high-temperature, ...view Hot Extrusion vs Piercing in Nickel Alloy Seamless Pipe ProductionJanuary 19, 2026Hot extrusion is generally preferred for high-alloy, difficult-to-deform nickel alloys, while piercing (Mannesmann process) is widely used for carbon steel and lower-alloy seamless pipes. In nickel al...view

Hot Extrusion vs Piercing in Nickel Alloy Seamless Pipe ProductionJanuary 19, 2026Hot extrusion is generally preferred for high-alloy, difficult-to-deform nickel alloys, while piercing (Mannesmann process) is widely used for carbon steel and lower-alloy seamless pipes. In nickel al...view The Complete Guide to Premium Stainless Steel Butt-Welded Fittings from Fujian Guangxin PipeTechJuly 1, 2025Leaking flanges causing downtime? Our precision stainless steel butt-welded fittings form permanent, leak-proof connections built for high-pressure, corrosive, and extreme-temperature applications. Fu...view

The Complete Guide to Premium Stainless Steel Butt-Welded Fittings from Fujian Guangxin PipeTechJuly 1, 2025Leaking flanges causing downtime? Our precision stainless steel butt-welded fittings form permanent, leak-proof connections built for high-pressure, corrosive, and extreme-temperature applications. Fu...view Inconel vs Monel vs Hastelloy Pipes: What's the Difference?January 19, 2026Inconel pipes are selected for high-temperature and high-stress environments, Monel pipes excel in seawater and hydrofluoric acid service, and Hastelloy pipes are preferred for extreme corrosion resis...view

Inconel vs Monel vs Hastelloy Pipes: What's the Difference?January 19, 2026Inconel pipes are selected for high-temperature and high-stress environments, Monel pipes excel in seawater and hydrofluoric acid service, and Hastelloy pipes are preferred for extreme corrosion resis...view How Duplex Stainless Steel Pipe Performs in High-Temperature and High-Pressure EnvironmentsSeptember 15, 2025Duplex stainless steel pipes have become indispensable in industries requiring both high strength and excellent corrosion resistance. Known for their balanced microstructure of austenite and ferrite, ...view

How Duplex Stainless Steel Pipe Performs in High-Temperature and High-Pressure EnvironmentsSeptember 15, 2025Duplex stainless steel pipes have become indispensable in industries requiring both high strength and excellent corrosion resistance. Known for their balanced microstructure of austenite and ferrite, ...view