Leaking pipe connections costing you time and money? The right flange can make all the difference. Flanges provide secure, leak-proof joints in pipelines, valves, and equipment—but choosing the wrong type can lead to failures, leaks, and safety hazards. Flanges are essential for high-pressure, high-temperature, and corrosive piping systems. The most common types include Weld Neck, Slip-On, Threaded, Socket Weld, RTJ, and Blind Flanges—each offering unique benefits for different industrial applications.

Selecting the right flange improves system reliability, reduces maintenance, and extends service life. Below, we break down top flange types and when to use them.

Problem: Pipe vibrations and pressure surges weakening joints? Weld Neck Flanges (WNF) solve this with their robust design.

Solution: These flanges feature a tapered hub that reinforces the connection, reducing stress concentration points. They're ideal for extreme conditions, including oil & gas, petrochemicals, and power plants.

✔ High-pressure resistance – Designed for ASME Class 150 to 2500

✔ Leak-proof welding – V-butt welding ensures full penetration

✔ Smooth flow transition – Reduces turbulence at connections

✔ Critical for high-risk systems – Oil refineries, offshore platforms

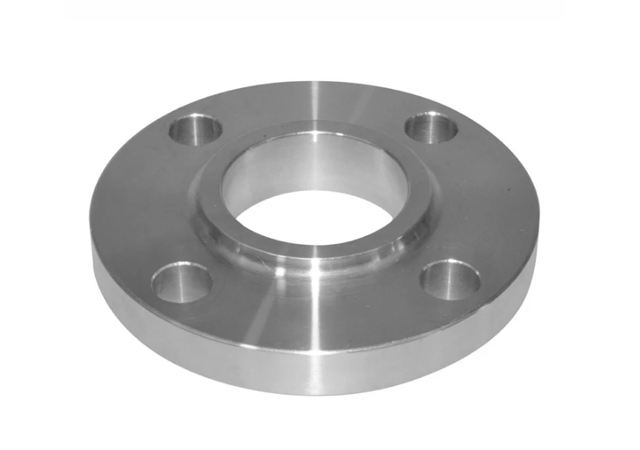

Problem: Need fast installation without precision alignment? Slip-On Flanges simplify the process.

Solution: These flanges slide over the pipe and require only fillet welding, making them perfect for low-pressure water, air, and chemical lines where fast assembly is crucial.

✔ Low-pressure systems (Below Class 300)

✔ Easier alignment – No need for exact pipe-end prep

✔ Cost-effective – Requires less welding than Weld Neck

✔ Common uses: HVAC, firefighting pipelines

Problem: Working in hazardous areas where welding is unsafe? Threaded Flanges provide a secure connection without heat.

Solution: These flanges screw onto the pipe, eliminating welding. They're ideal for explosive environments like gas stations and small-bore piping.

✔ Explosion-prone zones – Avoids sparks from welding

✔ Quick assembly/disassembly – Useful for maintenance-heavy systems

✔ Small-diameter pipes (Up to 4 inches)

⚠ Not recommended for high-pressure – Risk of thread leakage

Problem: Need a stronger connection than threaded flanges? Socket Welds provide stability in tight spaces.

Solution: The pipe fits into the flange socket, welded internally for a smooth seal. Perfect for high-pressure steam, gas, and corrosive fluids.

✔ Stronger than threaded – Welded joint withstands vibration

✔ Smooth bore – Minimizes pressure drop

✔ No crevice corrosion – Unlike threaded alternatives

✔ Used in: Boiler systems, hydraulic lines

Problem: Need to close off a pipeline for maintenance? Blind Flanges act as secure end caps.

Solution: These solid discs bolt onto other flanges to safely isolate sections during repairs or future expansions.

✔ Pipeline testing – Used in hydrostatic pressure tests

✔ Future expansion readiness – Easy to reopen when needed

✔ Emergency sealing – Quick shutdown of damaged lines

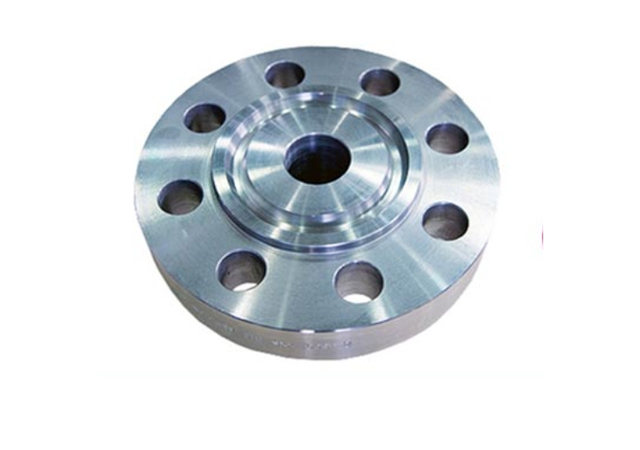

Problem: Losing pressure in critical systems? RTJ flanges create a metal-to-metal seal for zero leaks.

Solution: These flanges use a grooved ring (usually soft iron or stainless steel) that compresses under bolt pressure, perfect for refineries and offshore drilling.

✔ Highest seal integrity – For pressures over 2500 psi

✔ Resistant to thermal cycling – Unlike gaskets

✔ Common in: Oil & gas wellheads, high-pressure steam

Flange selection depends on pressure, temperature, material, and safety needs. Here's a quick guide:

| Flange Type | Best For |

| Weld Neck | High pressure/vibration |

| Slip-On | Quick installation |

| Threaded | No-weld environments |

| Socket Weld | Small-diameter strength |

| Blind | Pipeline isolation |

| RTJ | Extreme sealing |

At Guangxin PipeTech, we manufacture ASME/EN-compliant flanges in stainless steel, duplex, and carbon steel with full material traceability. Contact us for custom solutions.

Butt Welded vs Socket Welded Fittings: What's the Difference?December 8, 2025In industrial piping systems, choosing the right type of fitting is crucial for ensuring safety, efficiency, and long-term reliability. Two of the most common types are butt welded fittings and socket...view

Butt Welded vs Socket Welded Fittings: What's the Difference?December 8, 2025In industrial piping systems, choosing the right type of fitting is crucial for ensuring safety, efficiency, and long-term reliability. Two of the most common types are butt welded fittings and socket...view Material Selection for Integral Flanges: A105 vs Alloy SteelJanuary 19, 2026Carbon steel A105 is typically selected for integral flanges in moderate pressure and temperature services, while alloy steel is chosen when higher temperature strength, creep resistance, or enhanced ...view

Material Selection for Integral Flanges: A105 vs Alloy SteelJanuary 19, 2026Carbon steel A105 is typically selected for integral flanges in moderate pressure and temperature services, while alloy steel is chosen when higher temperature strength, creep resistance, or enhanced ...view Application Fields of Stainless Steel Seamless PipesSeptember 15, 2025Why Stainless Steel Seamless Pipes Are Essential in Modern IndustriesStainless steel seamless pipes are widely recognized for their durability, corrosion resistance, and ability to perform under high-...view

Application Fields of Stainless Steel Seamless PipesSeptember 15, 2025Why Stainless Steel Seamless Pipes Are Essential in Modern IndustriesStainless steel seamless pipes are widely recognized for their durability, corrosion resistance, and ability to perform under high-...view Inconel vs Monel vs Hastelloy Pipes: What's the Difference?January 19, 2026Inconel pipes are selected for high-temperature and high-stress environments, Monel pipes excel in seawater and hydrofluoric acid service, and Hastelloy pipes are preferred for extreme corrosion resis...view

Inconel vs Monel vs Hastelloy Pipes: What's the Difference?January 19, 2026Inconel pipes are selected for high-temperature and high-stress environments, Monel pipes excel in seawater and hydrofluoric acid service, and Hastelloy pipes are preferred for extreme corrosion resis...view Why Seamless Nickel Alloy Pipe Is a Preferred Choice for Marine ApplicationsSeptember 15, 2025Seamless nickel alloy pipes have become a key material in marine engineering due to their exceptional corrosion resistance, high mechanical strength, and reliability in extreme environments. These pip...view

Why Seamless Nickel Alloy Pipe Is a Preferred Choice for Marine ApplicationsSeptember 15, 2025Seamless nickel alloy pipes have become a key material in marine engineering due to their exceptional corrosion resistance, high mechanical strength, and reliability in extreme environments. These pip...view Why Seamless Pipes Are Preferred in High-Pressure EnvironmentsDecember 8, 2025When operating in high-pressure systems — such as oil refineries, chemical plants, or power generation lines — reliability is non-negotiable. Engineers and procurement managers consistently choose s...view

Why Seamless Pipes Are Preferred in High-Pressure EnvironmentsDecember 8, 2025When operating in high-pressure systems — such as oil refineries, chemical plants, or power generation lines — reliability is non-negotiable. Engineers and procurement managers consistently choose s...view