Flat face flanges are selected for equipment-sensitive and low-pressure systems, raised face flanges suit most standard industrial piping, and RTJ flanges are used in high-pressure, high-temperature, and critical service environments. The correct choice depends on pressure class, gasket type, connected equipment, and long-term sealing requirements—not on interchangeability or cost alone.

Choosing the wrong flange face can lead to gasket failure, flange damage, or recurring leakage, even when the product comes from a qualified flat face flange factory or flange manufacturer.

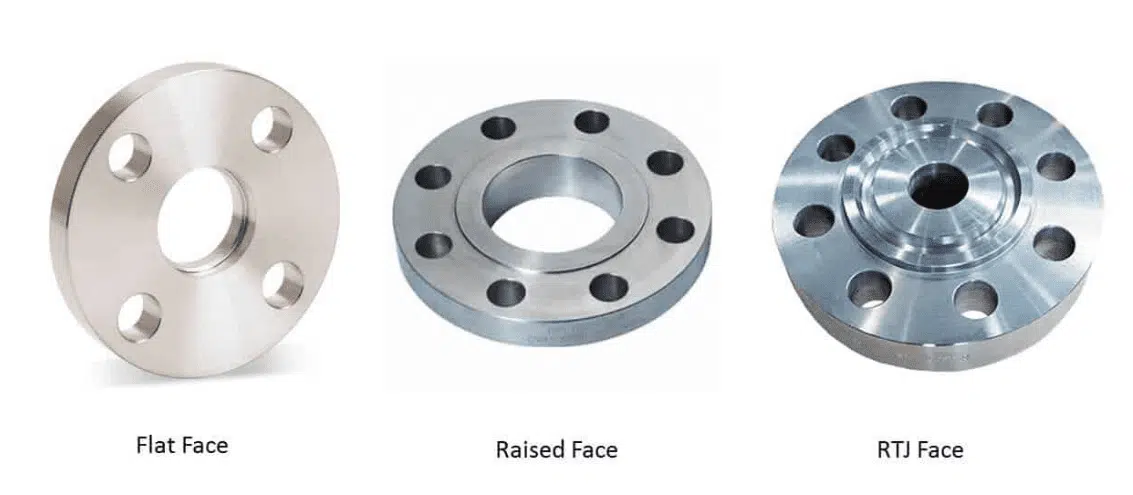

The primary differences lie in sealing surface geometry, gasket type, and pressure capability.

Flat Face (FF): Entire flange face is flat; uses full-face gaskets

Raised Face (RF): Raised sealing surface around the bore; uses ring or spiral wound gaskets

Ring Type Joint (RTJ): Machined groove for metal ring gasket; metal-to-metal sealing

Each design is optimized for a specific range of operating conditions.

Flat face flanges are used when uniform gasket compression and equipment protection are critical.

They are typically specified when:

Connecting to cast iron or ductile iron equipment

Equipment flanges cannot tolerate bending stress

Pressure ratings are relatively low (commonly up to 300#)

Full-face gaskets are required by equipment manufacturers

A reliable flat face flange factory ensures strict flatness control, which is essential for preventing flange distortion and gasket leakage.

Raised face flanges are the default option in most ASME B16.5 piping systems.

They are preferred because:

The raised sealing surface concentrates gasket load

Sealing performance is stronger than flat face designs

They support a wide range of pressure classes

They are compatible with most steel piping systems

For general industrial service, raised face flanges provide a good balance between sealing reliability and installation flexibility.

RTJ flanges are designed for severe service conditions.

Their defining features include:

Precision-machined gasket grooves

Use of metal ring gaskets (R-type, RX, BX)

Metal-to-metal sealing under high bolt load

RTJ flanges are commonly used in:

Oil and gas production

Refineries

High-pressure, high-temperature pipelines

Critical safety systems

Unlike flat face or raised face flanges, RTJ connections are not forgiving of installation errors and require precise machining and torque control.

They are not directly interchangeable without modification.

Flat face flanges should not be bolted to raised face flanges unless the raised face is machined flat

RTJ flanges require matching groove geometry and compatible ring gaskets

Mixing flange types without engineering review can introduce bending stress or sealing failure

This is why correct selection at the design stage is far more effective than adapting components later.

Gasket compatibility is a deciding factor.

| Flange Type | Gasket Type | Sealing Mechanism |

Flat Face | Full-face gasket | Uniform surface compression |

Raised Face | Spiral wound / ring gasket | Concentrated gasket stress |

RTJ | Metal ring gasket | Metal-to-metal sealing |

Selecting a flange without considering gasket behavior often results in leakage, even when pressure ratings appear sufficient.

RTJ flanges are the preferred choice for high-pressure and critical service.

Raised face flanges handle moderate to high pressures effectively but rely on gasket integrity. Flat face flanges are generally limited to low-pressure systems due to their load distribution characteristics.

Pressure capability should always be evaluated together with temperature, media, and maintenance accessibility.

Standards strongly influence which flange type is appropriate.

ASME B16.5: Raised face is standard; flat face is used for special cases

DIN / EN systems: Flat face flanges are more common in certain PN ratings

API standards: RTJ flanges dominate high-pressure oil and gas applications

Compliance with the applicable standard ensures dimensional compatibility and inspection acceptance.

The decision should be based on:

Pressure and temperature conditions

Type of connected equipment

Gasket design

Applicable standards

Installation and maintenance strategy

Working with an experienced manufacturer—whether a flat face flange factory or a full-range flange supplier—helps align the product with real operating conditions instead of generic assumptions.

| Aspect | Flat Face (FF) | Raised Face (RF) | Ring Type Joint (RTJ) |

Sealing Method | Full-face gasket compression | Concentrated gasket compression | Metal-to-metal sealing |

Gasket Type | Full-face gasket | Spiral wound / ring gasket | Metal ring gasket (R, RX, BX) |

Pressure Range | Low | Medium to high | Very high |

Temperature Capability | Limited | Moderate to high | High to extreme |

Flange Face Geometry | Completely flat | Raised sealing surface | Precision-machined groove |

Tolerance to Misalignment | Higher | Moderate | Low |

Typical Standards | DIN / EN, special ASME | ASME B16.5 | ASME, API 6A |

Installation Difficulty | Low | Medium | High |

Typical Applications | Equipment connections, utilities | General industrial piping | Oil & gas, HPHT systems |

Interchangeability | Limited | Common standard | Not interchangeable |

Each flange face design serves a specific purpose:

Flat face flanges protect sensitive equipment and distribute load evenly

Raised face flanges offer versatile sealing for most industrial piping

RTJ flanges provide maximum sealing integrity for extreme service

Correct selection reduces leakage risk, protects connected equipment, and lowers lifecycle costs. In engineered piping systems, the right flange face is not an option—it is a requirement for safe and reliable operation.

Application Fields of Stainless Steel Seamless PipesSeptember 15, 2025Why Stainless Steel Seamless Pipes Are Essential in Modern IndustriesStainless steel seamless pipes are widely recognized for their durability, corrosion resistance, and ability to perform under high-...view

Application Fields of Stainless Steel Seamless PipesSeptember 15, 2025Why Stainless Steel Seamless Pipes Are Essential in Modern IndustriesStainless steel seamless pipes are widely recognized for their durability, corrosion resistance, and ability to perform under high-...view Inconel vs Monel vs Hastelloy Pipes: What's the Difference?January 19, 2026Inconel pipes are selected for high-temperature and high-stress environments, Monel pipes excel in seawater and hydrofluoric acid service, and Hastelloy pipes are preferred for extreme corrosion resis...view

Inconel vs Monel vs Hastelloy Pipes: What's the Difference?January 19, 2026Inconel pipes are selected for high-temperature and high-stress environments, Monel pipes excel in seawater and hydrofluoric acid service, and Hastelloy pipes are preferred for extreme corrosion resis...view Why Seamless Nickel Alloy Pipe Is a Preferred Choice for Marine ApplicationsSeptember 15, 2025Seamless nickel alloy pipes have become a key material in marine engineering due to their exceptional corrosion resistance, high mechanical strength, and reliability in extreme environments. These pip...view

Why Seamless Nickel Alloy Pipe Is a Preferred Choice for Marine ApplicationsSeptember 15, 2025Seamless nickel alloy pipes have become a key material in marine engineering due to their exceptional corrosion resistance, high mechanical strength, and reliability in extreme environments. These pip...view Flat Face Flange vs Raised Face Flange: Key DifferencesJanuary 19, 2026Flat face flanges are typically used in low-pressure or equipment-sensitive applications, while raised face flanges are preferred for higher pressure and temperature services where stronger gasket sea...view

Flat Face Flange vs Raised Face Flange: Key DifferencesJanuary 19, 2026Flat face flanges are typically used in low-pressure or equipment-sensitive applications, while raised face flanges are preferred for higher pressure and temperature services where stronger gasket sea...view Why Choose Guangxin PipeTech's Cold-Rolled Seamless Pipes?July 1, 2025Need precision pipes that won't fail under pressure? Our cold-rolled seamless technology delivers ultra-thin walls with unmatched consistency. Guangxin PipeTech's cold-rolling process transfor...view

Why Choose Guangxin PipeTech's Cold-Rolled Seamless Pipes?July 1, 2025Need precision pipes that won't fail under pressure? Our cold-rolled seamless technology delivers ultra-thin walls with unmatched consistency. Guangxin PipeTech's cold-rolling process transfor...view The Complete Guide to Premium Stainless Steel Butt-Welded Fittings from Fujian Guangxin PipeTechJuly 1, 2025Leaking flanges causing downtime? Our precision stainless steel butt-welded fittings form permanent, leak-proof connections built for high-pressure, corrosive, and extreme-temperature applications. Fu...view

The Complete Guide to Premium Stainless Steel Butt-Welded Fittings from Fujian Guangxin PipeTechJuly 1, 2025Leaking flanges causing downtime? Our precision stainless steel butt-welded fittings form permanent, leak-proof connections built for high-pressure, corrosive, and extreme-temperature applications. Fu...view