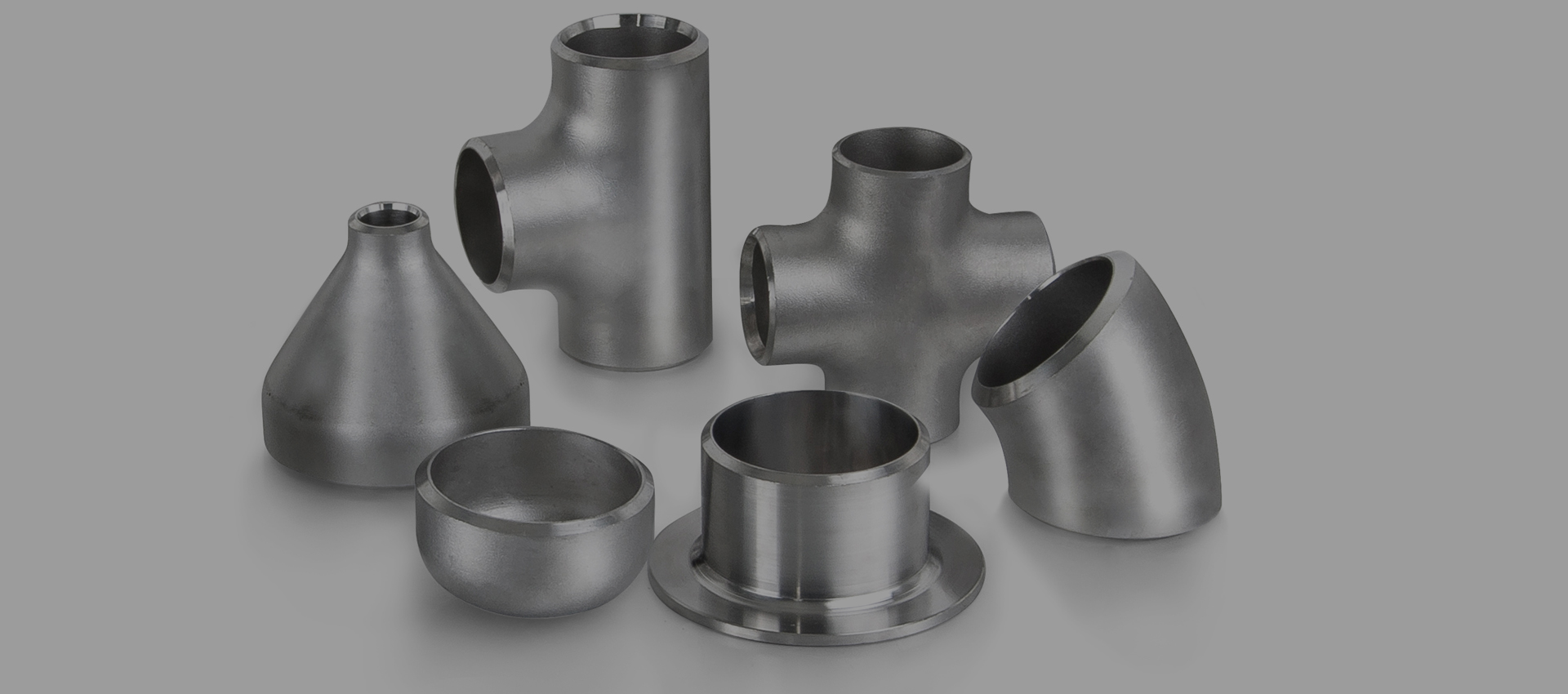

Advantages of Using Butt Weld Fittings

Butt weld fittings offer a permanent, leak-proof connection with excellent strength. Their smooth inner surface reduces pressure loss and turbulence, making them ideal for high-pressure and high-temperature applications. They also support better flow efficiency and allow for easy inspection, cleaning, and modification of piping systems.

Butt Weld Fittings vs Socket Weld Fittings

Butt weld fittings are welded directly to pipe ends, providing a stronger, more seamless connection with improved flow characteristics. In contrast, socket weld fittings use a socket for insertion and fillet welding, making them easier to install but less suitable for larger pipe sizes or high-stress systems. Butt welds are preferred for critical pipelines requiring structural integrity and corrosion resistance.

Common Applications of Butt Welded Fittings

Butt welded fittings are widely used in industries such as oil & gas, power generation, chemical processing, shipbuilding, and water treatment. They are ideal for transporting fluids under high pressure or temperature, and are commonly found in pipelines, heat exchangers, pressure vessels, and refineries.