Advantages of Using Flanges

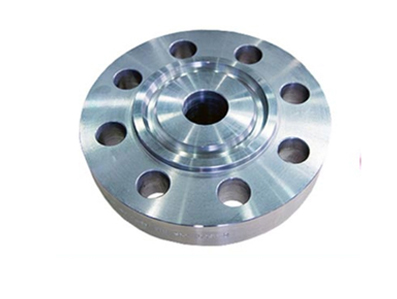

Flanges, as key components of stainless steel pipe fittings, offer significant benefits for industrial piping systems:

Secure Connections: Flanges provide robust, leak-proof joints, ensuring reliable connections in high-pressure and high-temperature environments like oil & gas and chemical processing.

Easy Installation and Maintenance: Their bolted design allows for quick assembly and disassembly, simplifying maintenance and system modifications.

Versatility: Available in materials like 304, 316, duplex stainless steel, and nickel alloys, flanges suit diverse applications, from corrosive marine environments to high-temperature power generation.

Standardized Compatibility: Conforming to ASTM, ASME, and API standards, our flanges ensure seamless integration with stainless steel seamless pipes and other fittings.

Durability: Stainless steel and alloy flanges resist corrosion and wear, extending system lifespan and reducing replacement costs.

Common Applications of Flanges

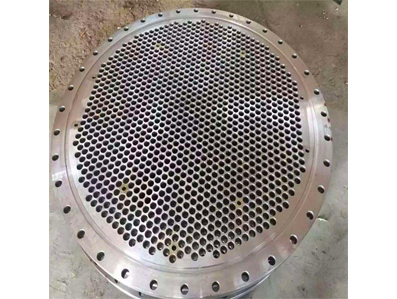

Flanges are essential stainless steel pipe fittings used across various industries for their versatility and strength:

Oil and Gas: Used in pipelines, refineries, and offshore platforms to connect stainless steel seamless pipes for safe fluid transport under high pressure.

Chemical Processing: Employed in reactors and piping systems to handle corrosive substances, leveraging the corrosion resistance of 316 and duplex stainless steel flanges.

Power Generation: Critical for boiler systems and steam lines, where high-temperature-resistant nickel alloy flanges ensure operational reliability.

Marine Systems: Applied in shipbuilding and offshore structures, where Monel and Hastelloy flanges withstand harsh seawater conditions.

Food and Beverage: Utilized in hygienic piping systems, with 304 stainless steel flanges ensuring compliance with sanitary standards.