Orifice flanges are designed for flow measurement, featuring pressure taps for differential pressure readings.

Sizes: 1” to 24”, pressure ratings: 300# to 2500#. Standards: ASME B16.36. Materials: A105, F316, Monel. Orifice plate installed between flanges with pressure taps.

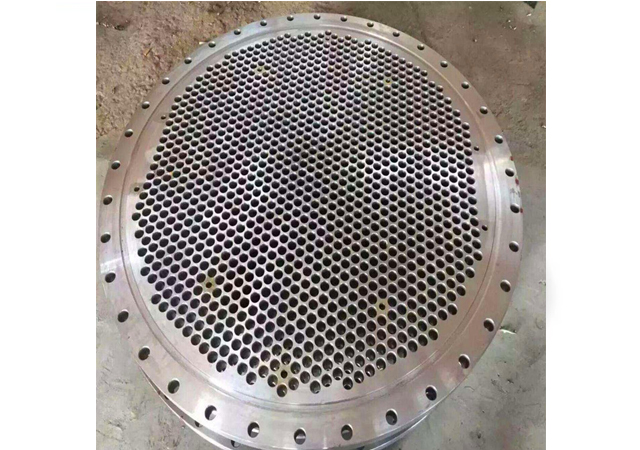

Orifice Flange – Flow Measurement Flange with Precision Taps

Orifice flanges are specially designed to measure flow rates in piping systems by holding orifice plates between a pair of flanges. These flanges typically come with pressure tap holes for differential pressure measurement. Available in ASME B16.36 standards, orifice flanges are commonly supplied in weld neck or slip-on types, with tapped holes and jack screws for easy plate removal. They are widely used in oil & gas, chemical, and power generation industries for accurate flow monitoring and control.

One of the main advantages of orifice flanges is their ability to accurately measure fluid flow without requiring separate flow meters or additional pipeline modifications. An orifice flange assembly integrates an orifice plate between two flanges, allowing the system to measure pressure differentials directly across the plate. This configuration simplifies the design of flow measurement systems in industrial pipelines, especially in oil and gas, chemical processing, and power generation industries where precise monitoring is essential.

Another major benefit is ease of installation and maintenance. Because the pressure tap holes are built directly into the flange pair, there is no need to drill or weld additional fittings onto the pipe. This reduces potential leak points, ensures safer installation, and allows for quick removal and replacement of the orifice plate for inspection or calibration. For operations that require frequent measurement checks, orifice flanges significantly reduce downtime and maintenance costs.

Standardization and compatibility are also key strengths. Orifice flanges are manufactured to international standards such as ASME B16.36, ensuring consistent dimensions and pressure ratings across different systems. They are available in a wide range of materials — including carbon steel, stainless steel, and alloy steel — to handle various temperature, pressure, and corrosive conditions. This makes them suitable for both liquid and gas flow measurement in demanding environments.

In addition, orifice flanges contribute to system reliability and accuracy. The precise machining of the flange bore and pressure taps ensures consistent pressure readings, which directly affects the accuracy of flow rate calculations. When properly installed and maintained, orifice flanges can deliver repeatable and dependable flow measurement over long service periods.

Finally, they offer cost efficiency compared to other flow measurement systems. Orifice flanges provide a durable, low-maintenance, and integrated solution that can be easily adapted to existing pipelines, eliminating the need for complex instrumentation setups. Their simplicity, reliability, and long service life make them a preferred choice for industrial process control and monitoring systems worldwide.