Seamless Pipe Specification

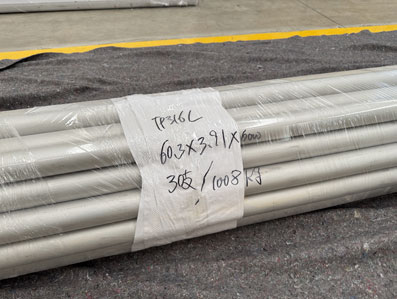

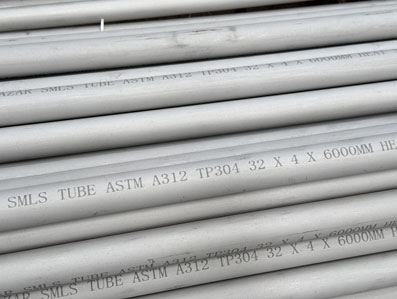

Seamless pipes range from 1/8” to 48” outer diameter with wall thicknesses SCH5 to SCH160 or XXS. Standards include ASTM A106, A53, API 5L, and ASME B36.10M. Seamless pipe material include carbon steel, stainless steel, and nickel alloys. Standard length is 6 meters. End types include plain, beveled, or threaded.

| Specification | Details |

| Outer Diameter | 6mm to 630mm (1/8" to 24" or custom sizes upon request) |

| Wall Thickness | 0.5mm to 50mm; SCH5 to SCH160, XXS |

| Length | 6 meters (standard), or random/fixed/custom lengths up to 12 meters |

| Material Grades | 304 / 304L, 316 / 316L, 321, 317L, 2205, 2507, Alloy 400, 600, 625, 825, C-276 |

| Material Types | Austenitic Stainless Steel, Duplex Steel, Super Duplex, Nickel Alloys |

| Standards | ASTM A312, A213, A269, A789, A790, ASME B36.10M, B36.19M, EN 10216, GB/T13296 |

| Manufacturing Process | Cold Drawn / Cold Rolled, Hot Pierced + Annealed |

| Testing Methods | 100% Eddy Current, Ultrasonic, Hydrostatic, PMI, Visual & Dimensional Tests |

| Surface Finish | Pickled, Bright Annealed (BA), Polished (up to 600 grit), Custom Finish |

| End Types | Plain End (PE), Beveled End (BE), Threaded End (TE), Customized Ends |

| Tolerances | As per ASTM, EN, or customer-specific tolerances |

| Certificates | EN 10204 3.1 / 3.2, Mill Test Certificate (MTC), NACE MR0175 (if required) |