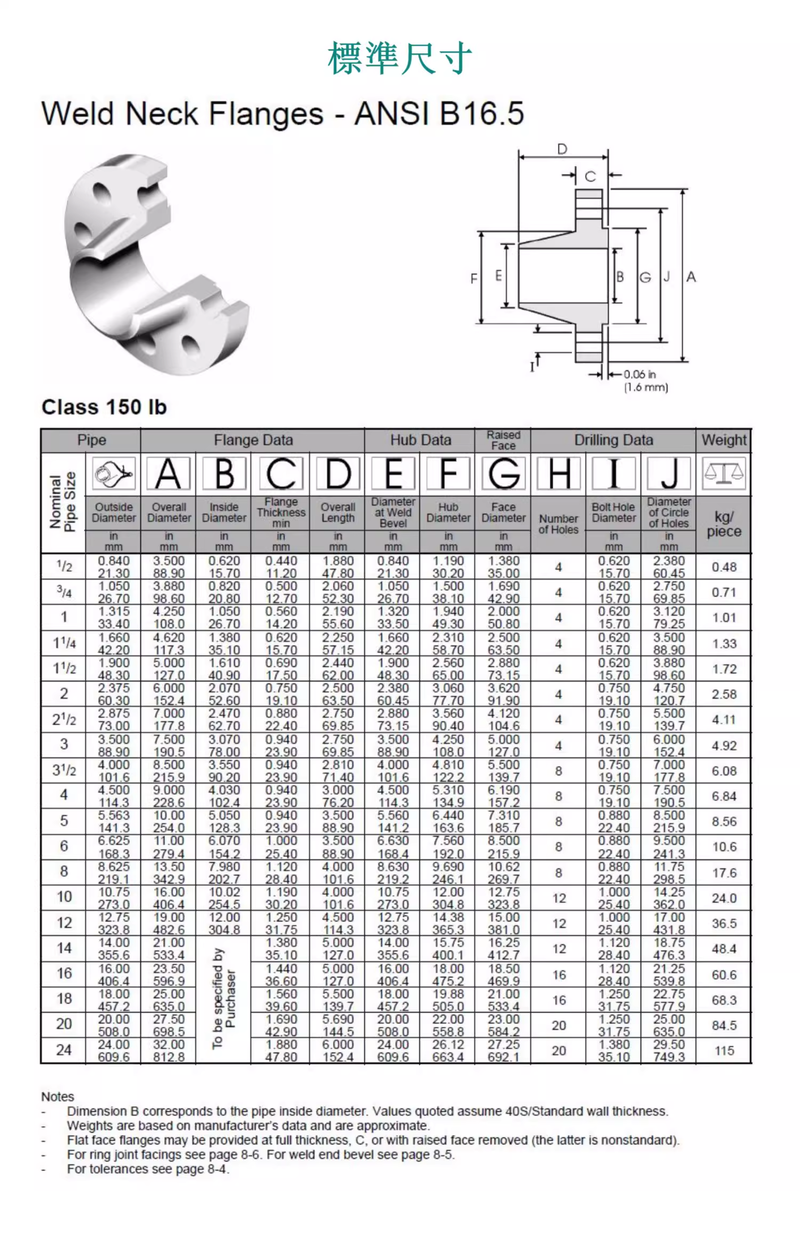

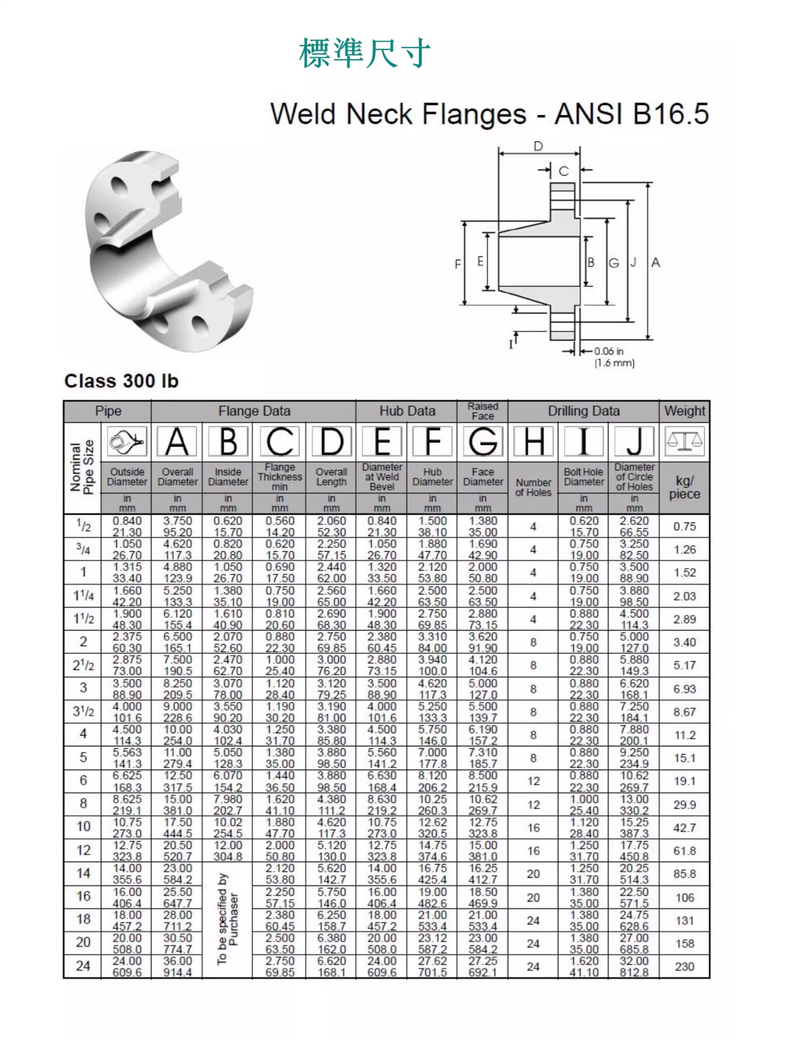

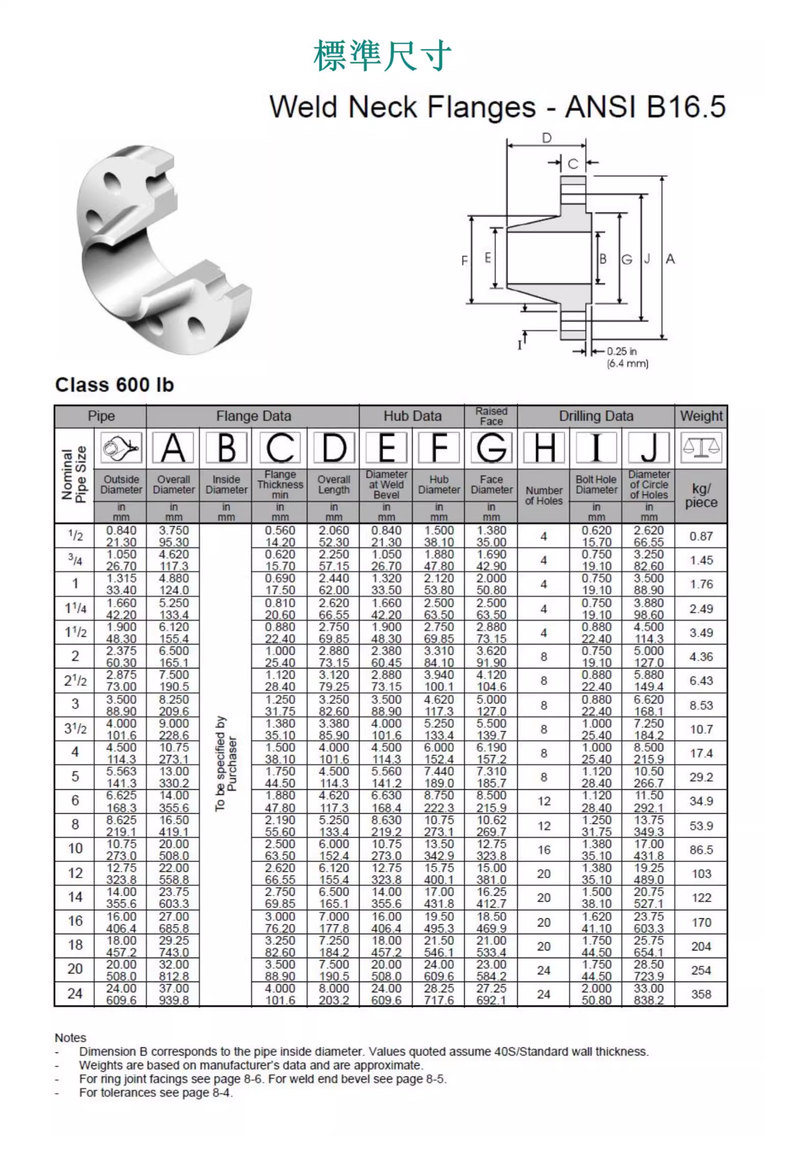

Weld neck flanges feature a long tapered hub for high-stress applications. They are butt-welded to pipe systems for strength and leak-proof performance.

We specialize in the production of high-quality industrial flanges, including stainless steel flanges, duplex steel flanges, and nickel alloy flanges, widely used in oil & gas, petrochemical, power generation, marine, and other demanding applications.

Stainless Steel Flanges: Manufactured from premium grades such as 304, 316L, and 321, these flanges offer excellent corrosion resistance, high temperature tolerance, and mechanical strength—ideal for general and moderately corrosive environments.

Duplex Steel Flanges: Made from grades like 2205 and 2507, duplex flanges combine the strength of ferritic steels with the corrosion resistance of austenitic steels. They provide superior resistance to pitting, crevice corrosion, and stress corrosion cracking.

Nickel Alloy Flanges: Engineered for extreme environments, our nickel alloy flanges (including grades such as Alloy 625, 825, and C276) deliver outstanding performance under high temperatures, high pressures, and aggressive corrosive conditions.

All flanges are manufactured in accordance with international standards such as ASME, ASTM, EN, and DIN, and are available in a full range of sizes, pressure classes, and facing types (RF, RTJ, FF) to meet the specific needs of your project.